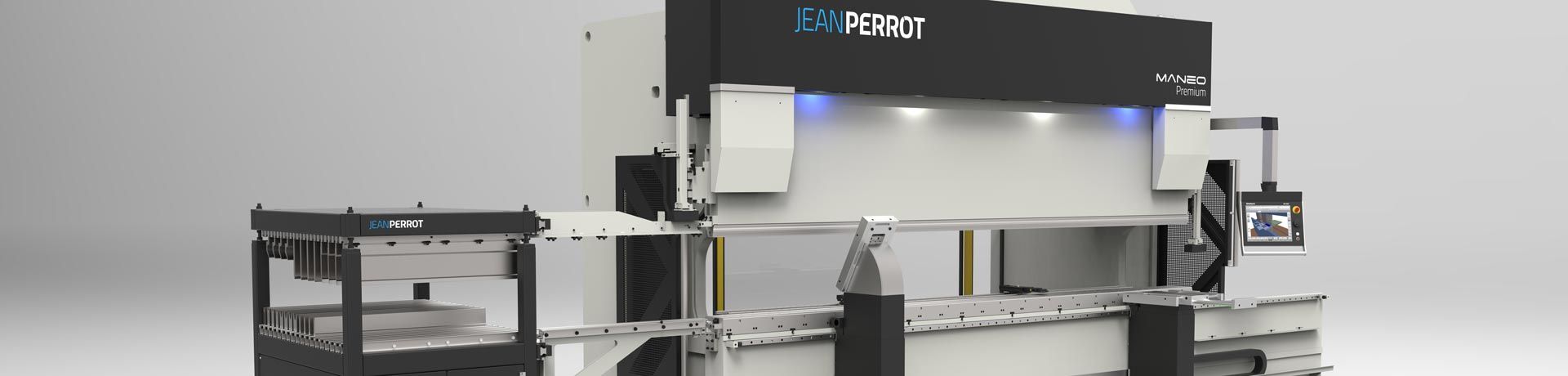

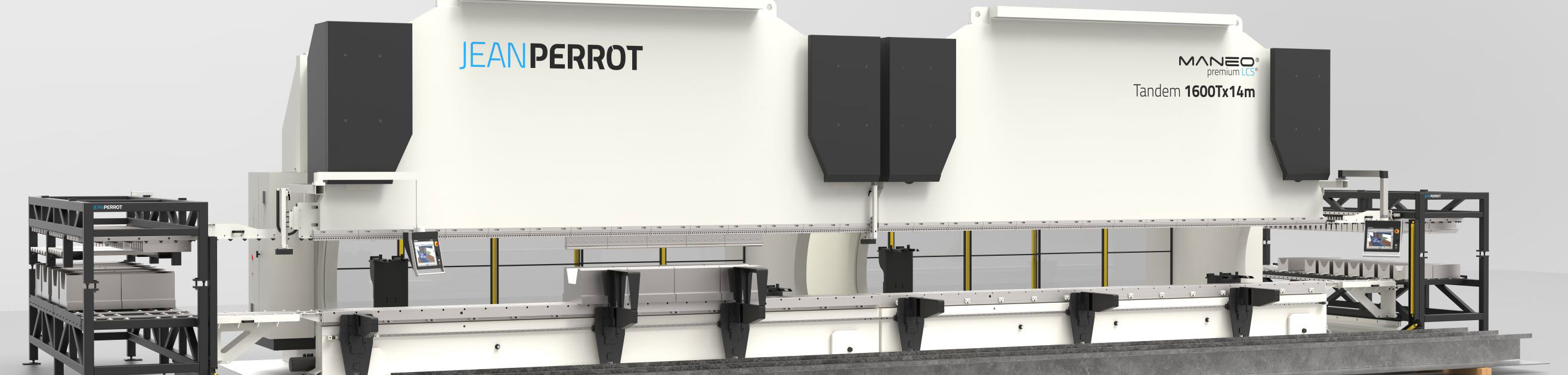

Press brakes MANEO Premium & MANEO Premium LCS

Sheet metal bending : Our press brakes MANEO Premium are high performance machines up to 2000 tons x 12 meters and more in Tandem or Tridem modes

. See More

Custom accessory equipment

We offer a wide range of standard & custom accessories in order to deliver turnkey press brake solutions adapted to your needs

See More

New electric press brake e-maneo

The essential for premium production E-MANEO premium can be distinguished by its modular, custom, and ecologically responsible design, high quality components, and ISO 9001 certified manufacturing procedures.

See More

Industry 4.0

As a pioneer in the industry 4.0 revolution, JEAN PERROT has developed a range of digitally enhanced services. Those services will assist you during the various phases of engineering development, operation, and maintenance.

See More

Automated bending: robotic press brake cell

We offer custom solutions to answer each of our clients' specific needs. Our automated bending cellsinclude press brake MANEO Premium LCS, robotic arms, accessories & additional modules to fit your needs.

See More

WELCOME TO JEAN PERROT

JEAN PERROT, a brand of PINETTE P.E.I. industrial engineering group, designs, manufactures and supplies sheet metal processing equipment : press brakes, automated robotic bending cells, shears, tube & profile benders, rolling machines, notching machines, punching machines…

From standard machines to turnkey automatic production lines including XXL heavy duty machines and custom tools, JEAN PERROT's team is at your disposal to define and answer all your needs related to sheet metal working machines.

‘’Innovation, expertise in sheet metal working processes and high quality of Jean Perrot’s services guarantee that your investment will be safe, mastered and adapted to your needs.’’

Press brake MANEO Premium : high performance bending

In order to guarantee optimal bending performance and unmatched ease of use, JEANPERROT has developed the next generation press brake series : MANEO Premium and MANEO Premium LCS. Machines from 2 to 12 meters long with a force from 75 to 2000 tons.

Electric press brake eMANEO Premium: high-performance bending

In order to guarantee optimal bending performance and unmatched ease of use, JEANPERROT has developed the next generation electric press brake series: eMANEO Premium and eMANEO Premium LCS.

Press brake for high speed bending MANEO GV

Press brake for high speed bending MANEO GV

JEAN PERROT, a brand of PINETTE industrial engineering group, is specialized in the design, manufacture and supply of standard or custom machines and turnkey systems for the sheet metal working industry.

Bending machines supplier for more than 50 years, JEAN PERROT has developped a press brake for high speed bending: the MANEO GV

PRESS BRAKE MANEO GV: CERTIFIED HIGH SPEED BENDING

JEAN PERROT has designed a high performance hydraulic system to boost the speed of the MANEO press brakes. From 75 to 250 tons, the MANEO GV is the fastest press brake on the market regarding approach, bending & return speeds. This machine produces even more than an electric press brake.

This high speed specific system - certified by an approved safety control inspection authority -, is particularly tailored to intensive use such as for sheet metal working subcontractors. MANEO GC can also be customized to enhance the productivity of more specific productions such as electric box and metal cabinets which need higher table / ram openings.

Features of the MANEO GV press brake:

- Design & Structure

- Rigid welded steel frame

- Ram guide on ball bearing rail

- Performances

- Approach speed: 280 mm/s

- Bending speed: 13 mm/s

- Return speed: 170 mm/s

- High tech components

- Chrome plated hydraulic cylinders

- Latest Lazer Safe safety controllers

- Sick light beam safety device

In order to reach unmatched productivity, our high speed bending machines can be associated with robots, conveyor systems & equipped with the LCS laser control system for angle measuring & correction. If you would like further information, please do not hesitate to contact us or to send us an online request for quotation.

Semi-automatic pres brake bending center

JEAN PERROT - a brand of PINETTE industrial engineering group - is specialized in the design and manufacture of standard or custom machinery and turnkey systems dedicated to sheet metal working industry.

In order to respond to the ever-growing needs to improve productivity & operator’s safety, JEAN PERROT has combined its extensive knowledge of industrial engineering with its expertise in sheet metal bending processes to design and supply a press brake with stress-relieved bridge frame & automatic tool change.

HIGH SPEED BENDING PRESS BRAKE CENTER

JEAN PERROT semi-automatic bending center is a high speed bending machine specifically designed for high-volume production runs. This 250 tons / 3 meters press brake is equipped with 3 different types of punches and 3 different types of dies. With the performance of this machine, a part which needs 9 bends is ready in less than 75 seconds !

3 press brakes in 1 custom engineered machine

With the sheet metal bending center MANEO, even complex parts can be bend in one step: you save time & remove buffer stocks between 2 or 3 bending phases.

Indeed, the automatic tool changing system allows to efficiently use specific bending processes such as joggle bending or hemming processes. The operator just need to place its part following the bending sequence.

Bending center MANEO is equipped with 3 types of punches & dies:

The press ram is equipped with 3 different lines of punches (height & profiles). Each line of punches is loaded or retracted by 2 hydraulic cylinders and the vertical movement is ensured by a ball bearing system for great speed & precision.

The lower table is equipped with 3 different line of dies (1 bend 90°, 2 joggle bends). Each die is associated with one punch. Dies move horizontally and automatically, according to the bending sequence. For perfect guidance over time, the bed is mounted on bronze alloy rails with graphite-inserts.

Features of the bending center MANEO:

- Stress-relieved bridge frame

- 2500 T / 3 meters

- CNC press brake with ESA GV numerical controls

- hydraulique dynamic crowning

- 3 axis back gauge (X, X2, R)

- Pneumatic strippers

- Front light beam devices to ensure operator’s safety / punch movement

- Latest Lazersafe operator protection system with 2 positions according to the height of punches.

- Approach speed : 275 mm / s

- Work Speed : 18 mm/s

- Automatic tool changing for 3 complete lengths of punches

- Automatic tool changing for 3 complete lengths of dies

Would you like further information? Whatever your project regarding high speed complex part bending, do not hesitate to contact us or to send us an online request for quotation.

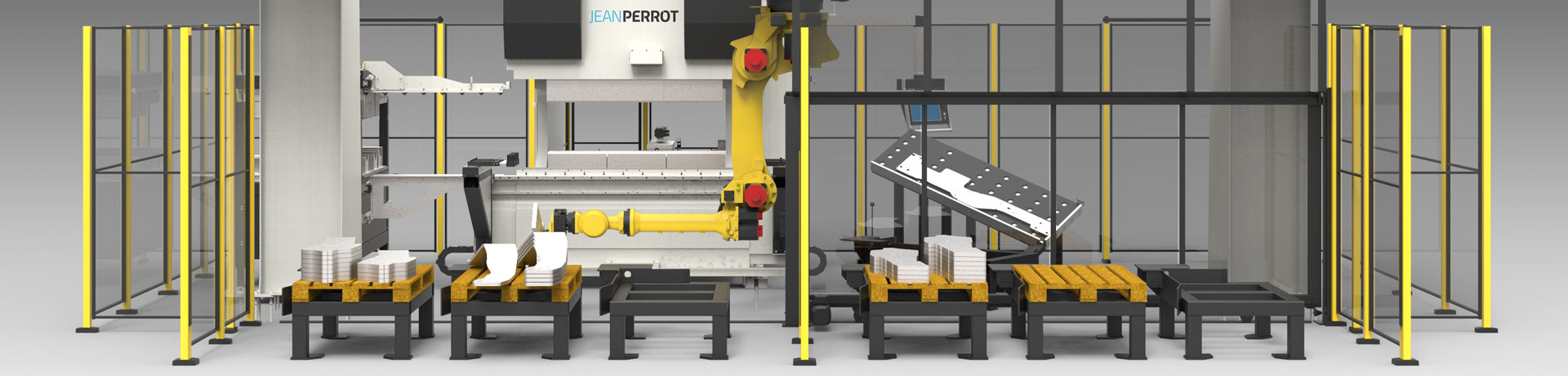

Automated bending: robotic press brake cell

When bending applications require high productivity, flexibility and precision, automated robotic bending quickly emerge as a better solution than manual bending operations.

As a consequence, JEAN PERROT, a brand of PINETTE group, has combined its extensive knowledge of industrial engineering with its expertise in sheet metal bending processes to design and offer automated bending solutions : the robotic press brake bending cell.

AUTOMATED ROBOTIC BENDING CELLS

We propose custom solutions in order to respond to the specific needs of each client. Our automated bending cells are composed of the press brake MANEO Premium LCS (Single machine, tandem or tridem modes), robots (fixed or rail-mounted), accessories & additional modules according to client’s need.

Turnkey solutions

- Complete integration of robotic solutions

- "All in one" solutions: complementary technological contributions

- Thorough analysis of your needs, and deep understanding of your needs

Expertise/Innovations

- Cobotics | Visions | Precision | Reliability

- Prehension | Shape recognition | Safety | Standard robotics

According to your needs, you offer you:

- Robotised bending cell

- E Cobot Bend™, the bender's companion - collaborative bending cell

- Automation of your logistics and flows

- Robotised inspection station

- Repetitive handling simplification

- Difficult working conditions are reduced

Press brake MANEO Premium LCS

JEAN PERROT CNC press brake MANEO Premium LCS regroups all our innovations in order to guarantee you optimal performances (high-speed, high-accuracy…) & unmatched ease of use:

- Up to 2000 tons x 12 meters with individual machines and 2000 tons x 32 meters in tridem (when three machines are connected together).

- Back gauges up to 12 axis

- Hydraulic dynamic crowning system up to 800 t / m capacity

- Motorized sheet followers

- CNC press brake with DELEM numerical control devices

- LCS angle measuring system:

This patented laser control system allows automatic bending angle measurement & correction (in real time). No matter how long the part might be, it ensures to obtain a very precise and high quality bending result.

This guarantees that each part is formed to the correct angle from the very first bend (and reduces costs and time due to trials).

The LCS makes possible production self-control and related traceability (control report generated for each bend of each part). If the LCS finds a bad part, the production line will stop and an alert message will be transmitted to limit losses.

Learn more about our press brake MANEO Premium LCS.

Robots (All brands)

- Polar or cartesian robots

- Multi-axis robots with suction, magnetic, or finger grippers

- Functions: unstacking, placing blanks to reference position, bending operations, loading / unloading and tool changes

- Capacity: up to 2 000 kilos

- Validation of part right placing (according to part reference position) by micro sensors on gauge’s heads.

Bending cell accessories

Our solutions are adapted to respond to the specific needs of each client, we can also add large range of accessories and additional modules:

- TOOLBOX modular system for tool storage, loading & unloading (single or double entry)

- Other tool storage cabinets

- Pallet flow management: conveyor systems for automatic pallet input and output

- Punches and dies cleaning systems

- Finished part storage solutions according to client's need

Options

- Bar code tool recognition

- Automated blank curve inspection before bending

- Double loading/unloading carousel for optimal safety

- Bespoke HMI and supervision

- Off-line programming

Bending Applications

- Heavy and large-sized parts like electric poles

- Ultra-precise bending like computer components

- Complex parts

- Medium & large volumes with short cycle times

- High speed bending

Examples

Would you like further information? Whatever your project related to automated bending, robotic bending cells & automatic press brake solutions, do not hesitate to contact us or to send us an online request for quotation.

Custom solutions for sheet metal bending

JEAN PERROT (a brand of PINETTE industrial engineering group), designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to the sheet metal working industry: press brakes, shears, profile & tube benders, rolling, notching & punching machines…

Among our machines & equipment, discover all our custom solutions for sheet metal bending.

AUTOMATED ROBOTIC BENDING CELLS

When bending applications require high productivity, flexibility and precision, automated robotic bending quickly emerge as a better solution than manual bending operations. As a consequence, JEANPERROT has developped an automated robotic bending cells with capacities up to 2000 tons x 12 meters for single press brakes and 2 000 tons x 32 meters in tridem mode (when three machines are connected together).

Semi-automatic bending center

JEANPERROT semi-automatic bending center is a high speed press brake specifically designed for high-volume production runs. This 250 tons x 3 meters press brake is equipped with 3 different types of punches and 3 different types of dies. With the performance of this machine, a part which needs 9 bends is ready in less than 75 seconds !

ULTRA HIGH SPEED BENDING

For our press brakes (single, tandems or even tridems), we have developed a specific system - certified by an approved safety control inspection authority -, in order to produce high speed bending machines : approach speed of 280 mm/s, working speed of 13 mm/s and return speed of 170 mm/s.

Our machines can also be equipped with accessories among which the LCS laser control system (automatic bend angle measurement & correction).

CUSTOM ACCESSORIES

In order to better meet your specifications and needs, JEANPERROT can also design and integrate custom accessories to your sheet metal bending machine.

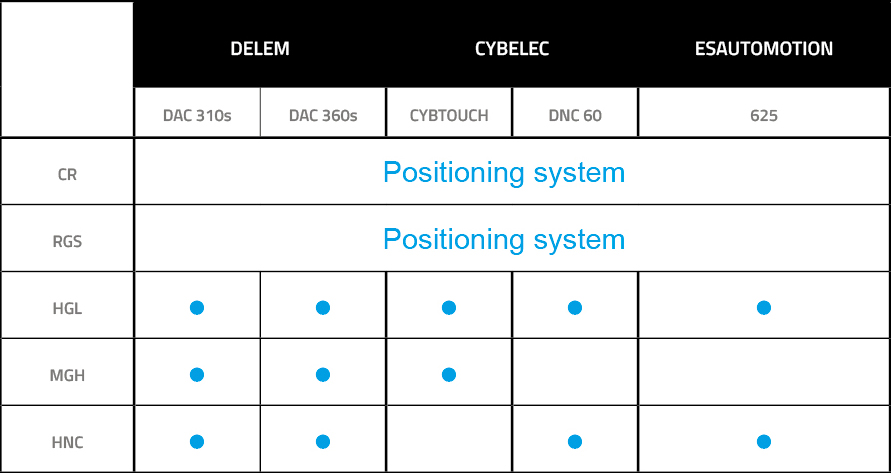

Numerical controls & positioning systems for CNC shears

JEAN PERROT designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to the sheet metal working industry: press brakes, robotic bending cells, shears, rollers, benders, punching & notching machines…

We provide CNC shears, equipped with the latest numerical control devices. It allows to optimise your productivity and to simplify operator’s work while ensuring their safety.

NUMERICAL CONTROL devices & positioning systems

Numerical control devices DELEM DAC

Features:

- Bright LCD screen

- Back / front gauge control

- Retract function

- Cutting angle control and gap control

- Stroke length limitation

- Force control

- Axes control

- Sheet thickness measurement

- Storage capacity: up to 100 different programs

For further information:

DELEM DAC 360s Numerical control device

DELEM DAC 310s Numerical control device

Numerical control devices CYBELEC CybTouch 6 & 8

Features:

- High-contrast touch screen, with vivid colors

- Intuitive and user-friendly interface

- Automatic calculations of the shear functions according to material specifications

- Back / front gauge control

- Retract function

- Cutting angle & gap control

- Complete programming of parts in seconds

- Quick set up of the machine with the EasyCut page

- Large cutting sequences and programs can be memorized

For further information:

CYBELEC CybTouch 6 numerical control device

CYBELEC CybTouch 8 numerical control device

ESAUTOMOTION S 625 numerical controls

Features:

- High-resolution touch screen

- Intuitive HMI

- Up to 3 axes management

- Part cut programming

- Large cutting sequences and programs can be memorized.

For further information:

ESA S 625 numerical control device

Would you like further information? Whatever your need related to shearing machine numerical controls, do not hesitate to contact us or to send us an online request for quotation.

Accessory equipment for hydraulic shears: rear belt conveyor

Industrial shears dedicated to sheet metal cutting represent an important part of our activity. In order to complement this product line, we have developed a rear belt conveyor with return to the front system which allows to simplify the operator’s tasks while optimizing the performance of our shearing machines.

REAR CONVEYOR WITH RETURN TO THE FRONT SYSTEM

The rear belt conveyor (single or multiple driven belt conveyors) simplifies not only the cutting step but also upstream & downstream operations :

The rear belt conveyor (single or multiple driven belt conveyors) simplifies not only the cutting step but also upstream & downstream operations :

- Maintaining sheet metal during positioning step

- Supporting sheet metal during the cutting step

- Sheet metal storage

- Sheet metal transfer toward the front or the back of the machine

- Evacuation of trim cuts in a scrap container

- 2 ways to set conveyor belt(s) operating features : time or speed.

Would you like further information? Whatever your project regarding shearing machines & accessories, do not hesitate to contact us or to send us an online request for quotation.

HGL shear : hydraulic swing beam shearing machine

JEAN PERROT designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to the sheet metal working industry: press brakes, robotic bending cells, shears, tube & pipe benders, rollers, punching & notching machines…

Among our shearing solutions, discover the HGL shear : a hydraulic swing beam shearing machine known for its great value price / quality & performances.

HGL SWING BEAM SHEAR : SHEARING QUALITY FOR EVERYONE

The robust steel welded machine frame ensures high reliability and excellent cutting quality. These shearing machines allow precise cuts with reducing deformations to a minimum. The low cutting angle on this type of shears allows to limit sheet metal twist and bow.

Thanks to Cybelec CybTouch 6 controller, the HGL shear is simple to use for operators. The machine also complies with the CE certification, ensuring completely safe working conditions.

Features of HGL hydraulic swing beam shear:

From 2 to 4 meters to cut sheet metal up to 6 mm thick.

Standard Equipment

User-friendly Cybelec CybTouch 8 numerical controls

User-friendly Cybelec CybTouch 8 numerical controls- Ball transfer table

- 1000 mm square arm

- Manual blade gap adjustment

- Shadow line lighting

- 1000 mm motorized ball-screw back gauge

- Clamping system with special protection for delicate sheet metal

- 2 front arm supports of 1000 mm

- CE certification

Options

Light beam safety device for finger protection (Safety Category 4)

Light beam safety device for finger protection (Safety Category 4)- Automatic blade gap adjustment

- Square arms of 2 / 2,5 / 3 / 3,5 and 4 meters

- Front arm supports of 1,5 / 2 / 2,5 / 3 / 3,5 and 4 meters

- Rear pneumatic sheet support

- Rear conveyor with return to the front system for metal sheets

- Shearing angle protractor (adjustable guide)

Would you like further information? Whatever your project regarding shearing machines, do not hesitate to contact us or to send us an online request for quotation.

RGS shear : mechanical shearing machine

Jean Perrot designs, manufactures and supplies machines - standard or custom - and turnkey systems dedicated to the sheet metal working industry: press brakes, robotic bending cells, shearing machines, rolling machines, bending machines, punching machines…

Among our shearing solutions, discover the RGS mechanical guillotine shear, a high speed shearing machine.

RGS MECHANICAL SHEAR: High speed shearing for everyone

RGS high speed mechanical shears are specially designed for the cutting of very thin metal sheets from delicate materials such as brushed or lacquered aluminium, copper, stainless steel or zinc.

Features of the RGS rapid mechanical shear:

From 1.5 to 3 meters to cut sheet metal from 0.4 to 3 mm thick.

Standard equipment

Standard equipment

- 1000 mm square arm

- 1000 mm front arm support

- Manual back gauge with ball bearing rails ( 600mm track)

Options

- Motorized back gauge

- Rear pneumatic sheet support

Would you like further information? Whatever your project regarding shearing machines, do not hesitate to contact us or to send us an online request for quotation.

HIGHLIGHTS

News

Presse review: JEAN PERROT IN ISMR

JEAN PERROT in the pages of International Sheet Metal Review

As part of the LAMIERA 2023 trade show in Milan, where our Italian subsidiary

Tolexpo 2021

Jean Perrot at Tolexpo 2021

Come and meet us from 6th to 9th September at Global Industry at Eurexpo Lyon!

booth 6G36

You will discover our cutting edge technologies and pro...